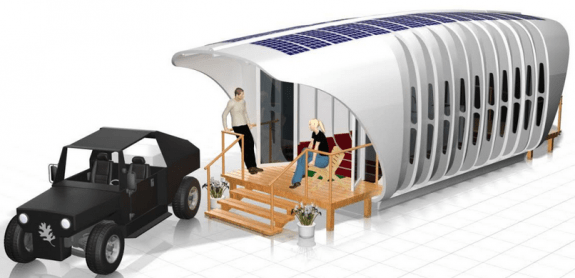

MHProNews understands the home utilizes a 3.2 kW solar photovoltaic system and has integrated low-cost vacuum insulated panels, able to charge the vehicle with its excess energy. An automatic control system optimizes the flow of energy between the car, the solar panels, the battery and the grid, using power management stategies.

A larger version of the 3D printer, named BAAM, is able to print large structures quickly, turning out up to 100 pounds of material each hour, printing objects as large as 20′ X 12′ X 6′. Roderick Jackson, Head of Building Envelope Systems Research at ORNL, says, “We will have a vehicle that not only is able to draw power from the building but is able to share power with the building. Now when the building needs power it [the vehicle] can provide that with its on-board natural gas generator and when the battery is low in the car, the building can charge the car. It’s a bi-direction flow of energy.”

The home is currently under construction, being printed in several sections at Clayton Homes, and will be on display at the Oak Ridge National Laboratory’s Energy Efficiency and Renewable Energy (EERE) Industry Day at the laboratory in Oak Ridge, Tennessee September 23, 2015. ##

(Image credit: 3DPrint)