The Daily Business News has covered this trend extensively over the years. Editorially, MHProNews publisher L. A. “Tony” Kovach has warned on the Masthead blog periodically for some years that cheap, imported units from other nations could undercut domestic modular and manufactured housing producers. Is that day now upon us?

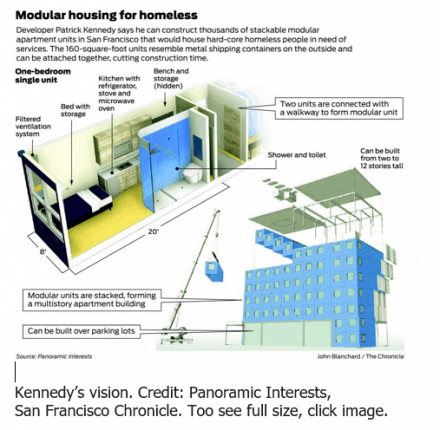

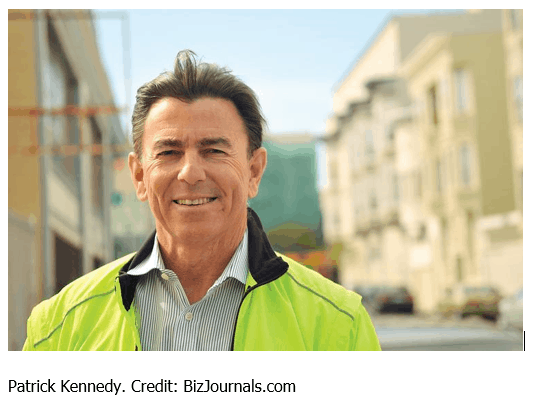

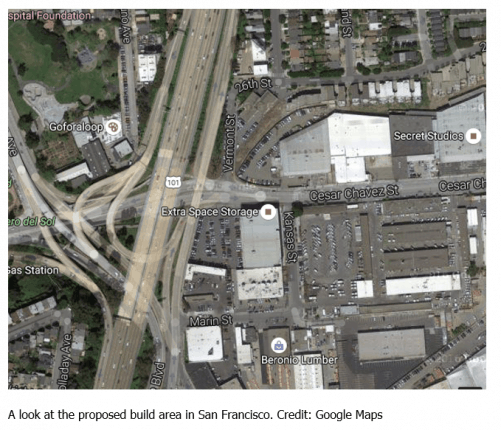

Kennedy has been pitching San Francisco City Hall on his plan for the past year, citing that his units can be built far faster than conventional structures for half the cost. His proposed location is above a publicly owned parking lot at Highway 101 and Caesar Chavez Street.

The Community Housing Partnership is also looking to build a 100-unit complex of modular units made of wood-framed components in a separate development.

San Francisco mayor Ed Lee has also pledged to spend $1 billion dollars over his second term to house 8,000 homeless people. While he likes the concept of modular housing, he mentioned that details needed to be worked out. This is where the hurdles begin.

The main construction unions that would be involved have taken issue with the fact that Kennedy’s metal boxes would be built in China, not made by American workers.

Local unions also believe building-code requirements are less stringent for modular construction.

Jeff Kositsky, head of the newly created Department of Homelessness and Supportive Housing also questions Kennedy’s proposal to build on city-owned land, saying there are already too many demands being made on scarce public property. While he takes issue, he’s not against the concept.

“I love the idea,” said Kositsky.

“The city is interested in finding ways to lower construction costs and the length of time it takes to build, and modular housing is certainly a promising development — and not just for homeless housing, but all housing.”

“We’ve been kind of holding back on pushing the subject further until we have something concrete for people to come see and experience,” said Kennedy. “But after we get this unit in front of my office, I want to talk more.”

“We should be able to work things out,” Kennedy said.

“I’m willing to sit down and talk if it meets code, provides good jobs, and if he’s not talking about using public land — that land is precious, and we have to be good stewards of it. We’re already master leasing from private landlords (of residential hotels). Why not this, too?” Kositsky said.

The head of the Community Housing Partnership, Gail Gilman, said that the organization’s wood-framed units would be constructed in Idaho.

“We should really have the city rally and come together to say, ‘Let’s try a couple of modular projects and see how it goes’ — because homelessness is a crisis here, and we need to try things.” Gilman said.

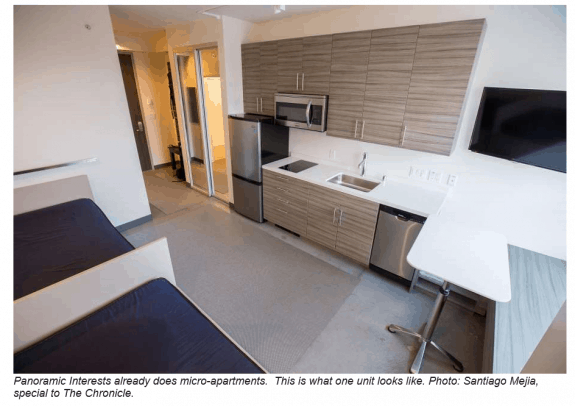

Kositsky shared that modular construction is not by definition “low-quality housing — there is plenty, used for hotels and dorms and more, that has been high-quality.”

The final word comes from Carol Galante, a UC Berkeley professor who specializes in affordable housing and urban policy.

“Modular construction saves time and money — at least 20 percent in construction costs and 40 percent in time — that’s been proven,” she said.

“We can do this.” ##

(Image credits are as shown.)

Submitted by RC Williams to the Daily Business News, MHProNews.