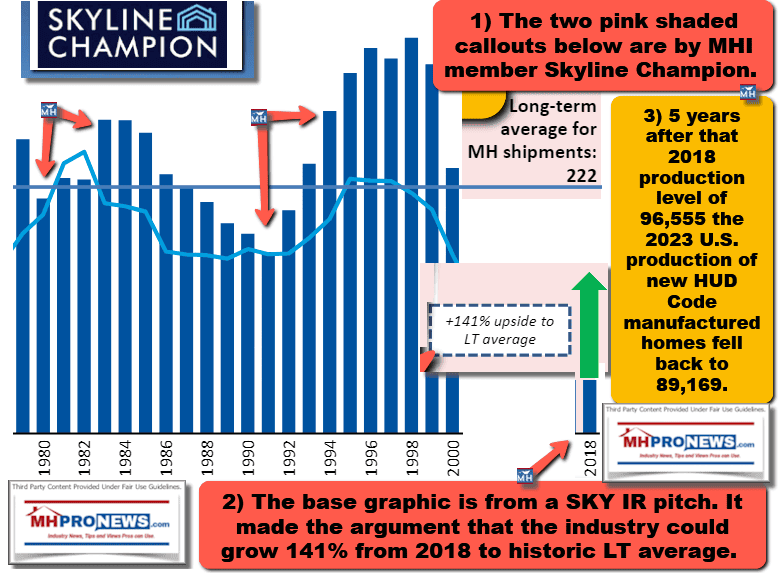

According to their website: “The New American Industrial Alliance (NAIA) is a multi-sector trade association dedicated to ensuring America is the techno-industrial leader of the world. We are builders, investors, and policymakers united in our commitment to steer America toward the policies, partnerships, and institutions that will unlock the full potential of our innovation engine and capital markets. America’s techno-industrial prowess is key to restoring manufacturing capacity, bolstering national security, rebuilding trust between citizens and their institutions, and ushering in a new era of prosperity for Americans of all economic classes. It is our duty to Reindustrialize.” Chris Power is a co-founder of the New American Industrial Alliance (NAIA) and he is the founder and CEO of Hadrian, an advanced manufacturing company, per his bio in brief in the article that follows in Part I. Part II will provide additional information and analysis through the lens of manufactured housing (a.k.a. MHVille, which is the apparently artificially diminished performance of the manufactured home industry in the 21st century, but which still has significant upside potential, per a range of third-party sources – see example below).

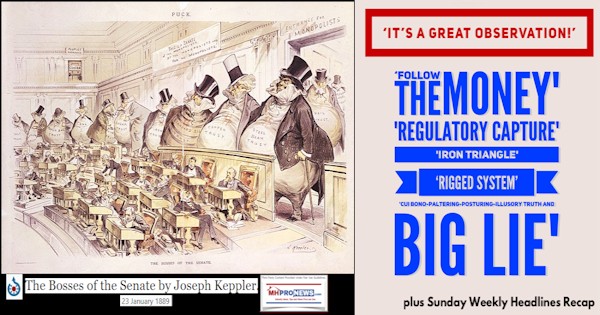

Specific elements of U.S. corporate and political leadership have been effectively pushing de-industrialization in the U.S. while moving production to countries such as China over the course of decades. While there have long been those who questioned or criticized the wisdom of offshoring production, it is increasingly apparent that those policies were flawed and have largely failed the working and middle classes of America. While there has been a push to de-industrialized the U.S. by some, Communist China’s leadership have their own policy of de-industrializing the U.S. An obvious motivation for that would be to neuter our nation’s ability to fight a potential future war. But that doesn’t change the fact that without the cooperation and investments made in China by U.S. and other Western national corporate interests, China wouldn’t be the production powerhouse it is today. The two illustrations below shed light on each of those broad themes.

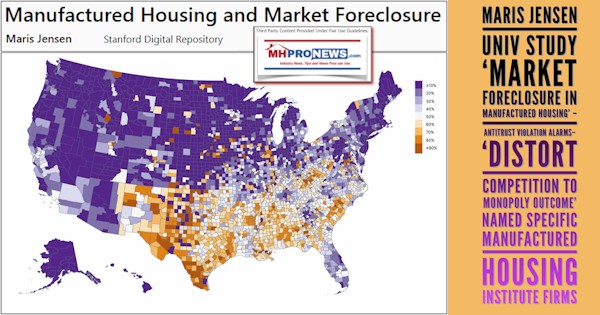

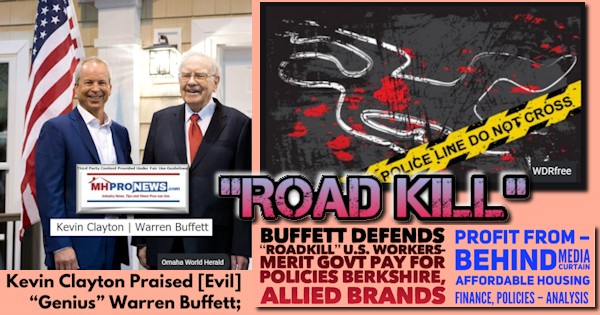

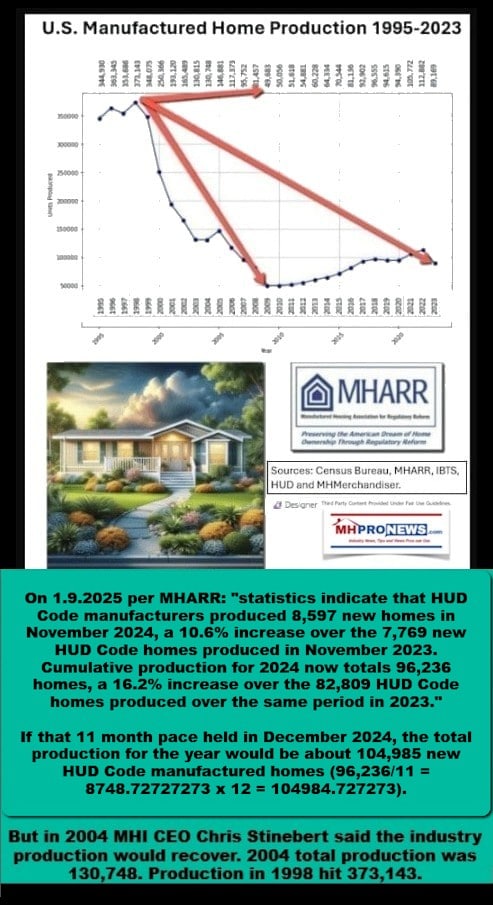

Stating the obvious, manufactured housing is a subset or part of the U.S. industrial base. While some have said that manufactured housing can’t readily have foreign competitors, one of the questionable remarks made by Kevin Clayton during a video interview linked below, it is apparent that Chinese and other prefabs are being shipped to the U.S. and have been for some years, as MHProNews has been periodically reporting.

More on the background and implications for these developments are found in Part II, further below.

Part I

Rebuilding American Manufacturing: It’s Not Just Plants, It’s People

Authored by Chris Power via RealClearPolitics and RealClearWire.

The latest spotlight on the crisis in American manufacturing may be on steel, but our nation has traded its manufacturing might for financial gains across all sectors – making the same fateful mistake that has befallen great civilizations throughout history. As a founder, CEO, and advocate for American industrial renewal, who’s building the world’s most advanced, efficient factories to counter China’s chokehold on manufacturing, I can tell you that America has just three years – not 10 – to rebuild our industrial base before falling critically behind.

The vice president and many of the new administration have demonstrated passion for reindustrializing the country and creating a jobs boom that has not been seen in this country for decades.

This is not just an economic challenge – it’s a moral imperative to secure our nation’s future while being good stewards of our resources, which include the people of this great country.

The good news is that American innovation and determination can overcome these challenges. In my own company, we’ve developed systems that can transform someone who’s never set foot in a factory into a highly productive team member in weeks, not years. We pay well, offer equity, and provide meaningful work contributing to national security. This isn’t about replacing American workers with automation – it’s about empowering them with technology to manufacture for America faster and better than ever before, creating new and better jobs along the way.

Likewise, the Trump administration’s commitment to reindustrialization, American manufacturing and our workforce can begin on Day One. To regain our competitiveness, we need the incoming administration to take four broad steps:

First, we must dramatically reform our permitting process for strategic manufacturing facilities. While China can build a factory in months, American companies often wait years for permits. This regulatory burden is crushing our ability to rapidly scale the production of critical components.

Second, we need to level the playing field against China’s predatory practices. This means addressing everything from raw material costs to energy rates to shipping subsidies. These artificial costs squeeze what American companies can pay their workforce.

When Chinese manufacturers can access materials and energy at a fraction of what American companies pay, we’re not competing on merit – we’re competing against a government-subsidized adversary that has been intentionally de-industrializing the U.S. for 30 years. Americans can compete, but not against the Chinese Communist Party making everything from energy to raw materials free. One hundred billion dollars of currently offshored manufacturing business from American companies sourcing in China could return overnight as a result of a more level playing field, creating a jobs boom unlike anything we’ve seen since the ’40s.

Third, we must ensure that manufacturers who receive government subsidies or revenue from the Department of Defense (DOD) make their supply chain 100% American. Too many of our tax dollars end up being outsourced to China and other competitive nations for 20% cheaper components from bad supply chain incentives. Tariffs will help, but we need a mandate to “make in America if you want to get paid by American taxpayers!”

And finally, we need to stop missing crucial opportunities and take big, bold bets on American manufacturing to signal to the CCP that we are serious about any offensive moves in Europe or the Pacific Theatre.

Take shipbuilding. In 2022, China built 800 commercial ships, while America built just one. Last week, the Congressional Budget Office (CBO) released its independent analysis of the U.S. Navy’s shipbuilding plan, warning that the number of battle force ships will decrease from 295 today to 283 ships in 2027, reducing the fleet’s firepower. Further, CBO predicts that over the next 30 years, “…the nation’s shipyards would need to produce substantially more naval tonnage than they have produced over the past 10 years. The rate of production of nuclear-powered submarines, in particular, would need to increase significantly.” Thankfully, President Trump’s pick for secretary of defense, Pete Hegseth, recognized the urgent need for shipbuilding in his confirmation hearing this month, signaling industrialization as a top priority of the next administration. In short, we need many more ships, and we need to build them now.

But what did President Biden do? He nixed a Navy proposal called the Shipyard Accountability and Workforce Support (SAWS) initiative that would have allowed U.S. shipbuilders to invest in their workforce and suppliers, stem the rising cost of submarine production through technological innovation, and allow 17 more boats to be built. SAWS achieves this by using taxpayer dollars more effectively without Congress having to appropriate another nickel.

Instead, Biden asked Congress for nearly $6 billion dollars as a Band-Aid to fix the problem.

SAWS represents an immediate, comprehensive approach to revitalizing American shipbuilding. On Day One, it will provide wage increases to 45,000 shipyard workers across the nation while smartly using authorities in the 2025 National Defense Authorization Act to fund both these wages and critical, cutting-edge shipyard technologies, helping our major primes and new market entrants build faster, smarter, and more efficiently. Through streamlined processes that will speed up ship and submarine production, along with careful resource management, SAWS is projected to save taxpayers over $20 billion while strengthening our industrial base and has a real chance to both fix our current issues and make a technology-driven manufacturing leap over the CCP ahead of the looming 2027 Pacific timeline.

In his first week, President Trump can pick up the ball the outgoing administration has dropped and send a signal to the CCP that he will not wait to rebuild American manufacturing strength. President Trump’s nominee for the White House Office of Management and Budget, Russ Vought, gets this. In 2020, he backed expanding the Navy. And today, the stakes couldn’t be higher. We have the innovation, the workforce, and the determination to succeed. What we need now is leadership that understands the urgency of our challenge and is willing to take bold action. Working together – government, industry, technology, and the American people – we can restore our God-given right to be the world’s industrial superpower – and ensure that the 21st century remains an American century.

The time for action, the time to start reindustrializing America, is now.

Chris Power is founder and CEO of Hadrian, an advanced manufacturing company, and is a co-founder of the New American Industrial Alliance (NAIA).

Part II – Additional Information with More MHProNews Analysis and Commentary

1) As with any fairly brief statement, Power’s remarks could merit added nuance and detail. That said, it is a useful introduction to the headline topics.

Today marks a new chapter, a powerful dawn for the American workforce, a shift in power we’ve waited too long to see. For years, they pretended we didn’t exist. They claimed they couldn’t find us, all while systematically replacing us.

Layoffs. PIPs. Reductions in Force. Job… pic.twitter.com/m8DgbHbD5O

— Alb (@amandalouise416) January 20, 2025

“We have ~7 years to fix American manufacturing or we’re cooked.”

I sat next to an Old Guard manufacturing CEO last night at dinner.

He dropped deep wisdom.

Here are 5 things we must do to win:

> Make Skilled labor High Status again

> Unite the Generations

> Rethink Higher Ed… pic.twitter.com/iY27teubXY— Ben Kohlmann 🇺🇸/acc (@benkohlmann) December 6, 2024

Rebuild American Manufacturing;

Rebuild American Workers;

Rebuild America https://t.co/6948zBiCba pic.twitter.com/WJEfBjx4h1— Grace Chong, MBI (@gc22gc) January 26, 2025

To bring about a resurgence in manufacturing, the Trump administration will need to embrace a broad program of reindustrialization—and promote the full development of the United States’ natural resources, argues @oren_cass. https://t.co/zAjVqPiLex

— Foreign Affairs (@ForeignAffairs) January 26, 2025

2) In case some have not been paying closer attention, it seems that President Trump 2.0 is quite aware of the array of needs and issues involved. By the way, the notion of $100 billion in new plants and U.S. investments is obviously low, because President Trump already announced a greater investment in the U.S. than that by a factor of 5 in just one ‘deal.’ Bringing Greenland by some means into the U.S. orbit is intended in part to deal with the Chinese rare earth minerals edge.

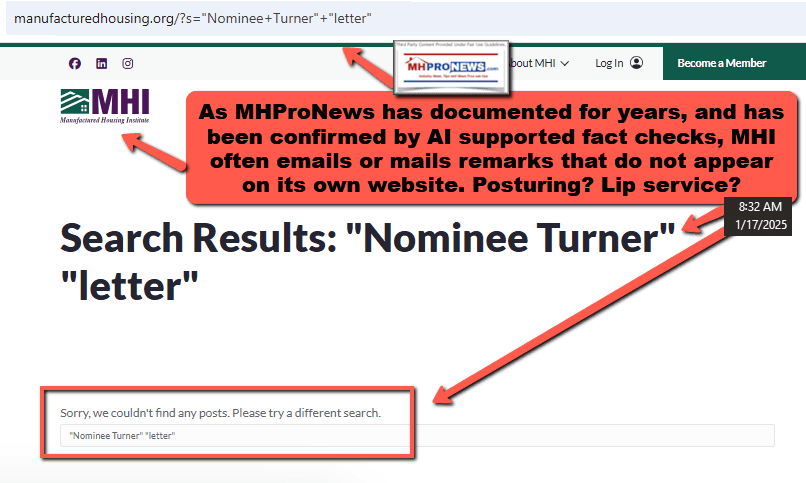

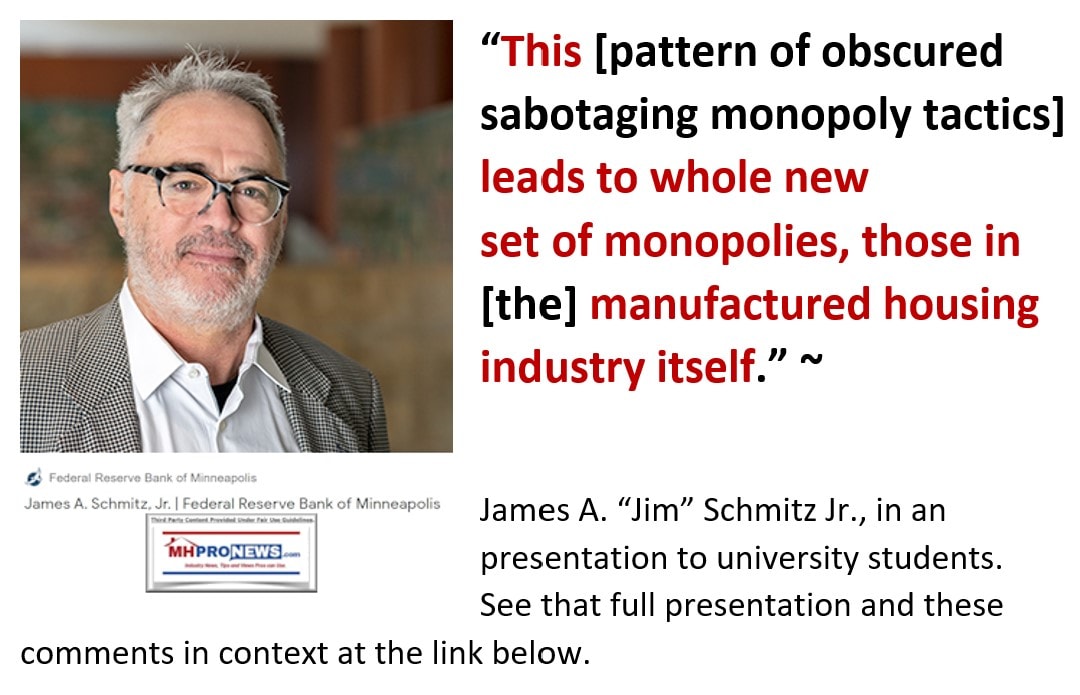

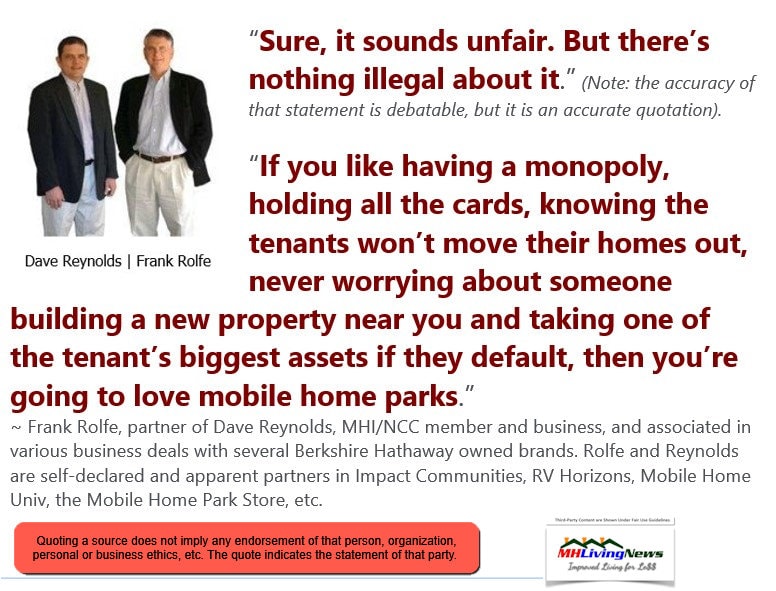

3) While the Manufactured Housing Institute (MHI) has made some tepid posturing-style statements, for those who have been plugged into MHProNews the troubling truth of these issues have been laid out by accurate reporting of an array of facts and evidence from within and beyond the boundaries of MHVille. Consider the following reports.

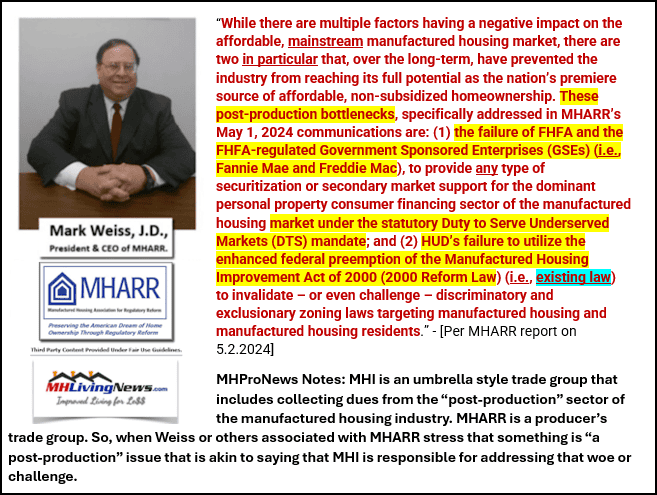

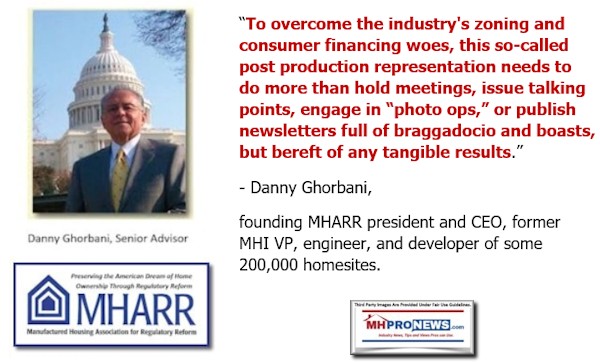

3) In stark contrast to MHI is the Manufactured Housing Association for Regulatory Reform (MHARR). While any good trade group seeks to work with both major parties, there is working with and there is ‘selling out’ to, which MHI seems to have sold out to the Biden-Harris agenda, as was documented using their own information and that of their key members in some of the articles linked above. By contrast, MHARR – while trying to work with the Biden-Harris regime – did not hide the fact that they saw the Trump Administration as a potential ally in their own agenda for regulatory reform. MHI postured, by MHARR made specific overtures. MHARR continued to do outreaches during the transition.

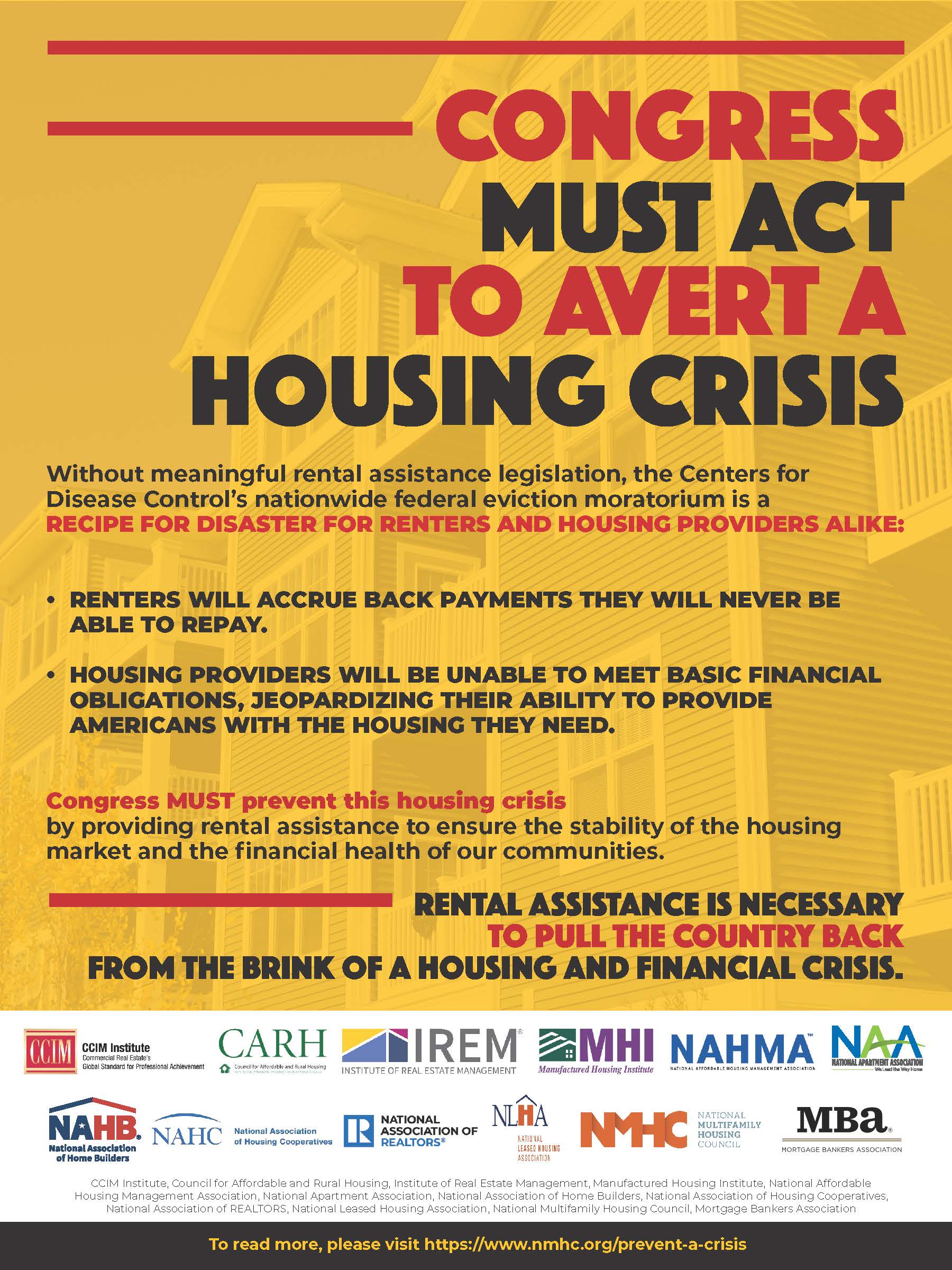

4) Trump in the devastation of the wildfires in California and the aftermath of Hurricane Helene in places like North Carolina has been talking about waving permits under emergency powers. Where is MHI to stand up, wave a very public flag with an ad or op-ed in a Washington, D.C. publication as they did (for posturing) before to help the competitors of the industry? While “enhanced preemption” under the Manufactured Housing Improvement Act of 2000 should be pressed 24/7/365 by MHI, it should be especially pressed during a post-disaster period when thousands of homes need to be replaced quickly. HUD Code manufactured homes can do that, but conventional builders can’t by their own admission.

5) There are reasons to believe that Trump 2.0 has learned the lessons of duplicitous behavior that limited the good that they were able to accomplish in the first term of President Trump.

6) Trump wants to drill, baby, drill. We also need to build, baby, build. Trump the builder should know that the National Association of Home Builders (NAHB) said that they can’t build a house that can make home ownership possible for most first-time homebuyers. $2 Trillion dollars a year in lost productivity is a lot of incentive to unleash the industry in a way that MHARR has been pressing throughout the 21st century, while MHI postures without doing what they should and could to get existing laws enforced.

New in depth report reveals facts, math, and evidence that make modern manufactured homes an essential part of HUD and local planning https://patch.com/florida/lakeland/can-t-solve-u-s-affordable-housing-crisis-without-factory-built-homes

There is always more to know. See the linked and related reports.

Again, our thanks to free email subscribers and all readers like you, as well as our tipsters/sources, sponsors and God for making and keeping us the runaway number one source for authentic “News through the lens of manufactured homes and factory-built housing” © where “We Provide, You Decide.” © ## (Affordable housing, manufactured homes, reports, fact-checks, analysis, and commentary. Third-party images or content are provided under fair use guidelines for media.) See Related Reports, further below. Text/image boxes often are hot-linked to other reports that can be access by clicking on them.)

By L.A. “Tony” Kovach – for MHProNews.com.

Tony earned a journalism scholarship and earned numerous awards in history and in manufactured housing.

For example, he earned the prestigious Lottinville Award in history from the University of Oklahoma, where he studied history and business management. He’s a managing member and co-founder of LifeStyle Factory Homes, LLC, the parent company to MHProNews, and MHLivingNews.com.

This article reflects the LLC’s and/or the writer’s position and may or may not reflect the views of sponsors or supporters.

Connect on LinkedIn: http://www.linkedin.com/in/latonykovach

Related References:

The text/image boxes below are linked to other reports, which can be accessed by clicking on them.’