There is much talk of the need to “do something” about our industry’s image. Wow, that’s some understatement!

But what? And how? And who will pay for the refurbishment?

It’s a deep problem. It’s hard to refurbish an image that was never really “furbished” in the first place! The MH industry has a lot of growing up to do, and it’s quite a challenge.

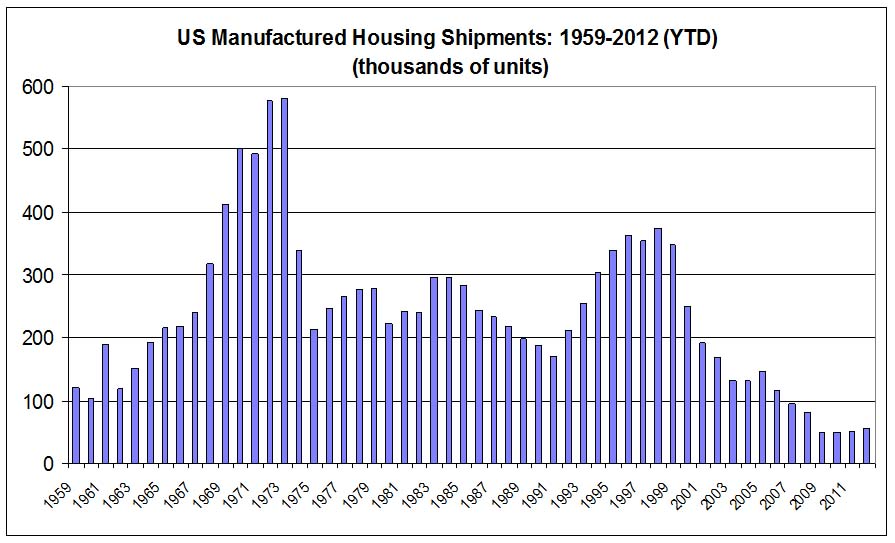

Tony Kovach recently published the following graph.

Our eyes jump to the trend of the past decade, which emphasizes the need to “do something.” I invite you to study the other end of that graph. The sixties.

In that decade, as today, the rule of thumb for a stick builder was to dedicate about half of construction cost to materials. That didn’t work for those building homes in factories. They had to build a product sturdy enough to ship a thousand miles on its own wheels, and if material content dropped below 60 percent—lock the factory doors. No reputable dealer would buy. In those days, despite buying all that material factory-direct and very efficient labor, the MH cost was far higher per square foot than a house (excluding land).

By the end of that decade, the rule of thumb—the MH optimum for sales maximization—was 70 percent material, 10 percent labor, 10 percent overhead and 10 percent pretax profit. In good years, that worked and profits rolled in. In bad years, you got hammered.

Sounds like a loser business?

Not if you knew your stuff. If you managed 30-plus inventory turns, collected cash on delivery of the homes, operated in a pole-barn factory and had nominal investment, you could operate on your supplier’s 30-days-same-as cash payment plan. Banks released floor-plan cash upon delivery of the home. 100 percent return on equity was not out of the question. But everything had to work.

Look again at Tony’s graph. Everything did work during that decade for those who managed well. A year of no sales increase was considered a recession.

Manufacturers had to master that formula or get out of the race. Competition was brutal, but everyone understood that no one could do it alone. Manufacturers, suppliers, dealers, developers and banks. All were highly profitable when they got their sums and strategies right.

The quality of manufactured homes soared and the cost of producing them plunged. Such was the magnitude of opportunity in the sleepy housing industry.

It was Skyline, Fleetwood and the like who got the publicity—biggest MH manufacturers, most profitable companies in the stock market and all that. Surely they should have stepped up to the plate and “done something” about the industry’s image?

Well, they did what they could, but their hands were tied. Every nickel of such a manufacturer’s profit would have funded just one percent of industry sales for an image-building program. And what, one might ask, could a manufacturer have done for its image more useful than investing in product improvement? That’s what the critics and customers requested, and rightly so.

The largest manufacturers each held less than 10 percent market share and had plenty of competition snapping at their britches. Which of those “leaders” should have stepped up to the plate and invested significant funds in the industry’s image? Sure the profits were good, but they didn’t stay that way.

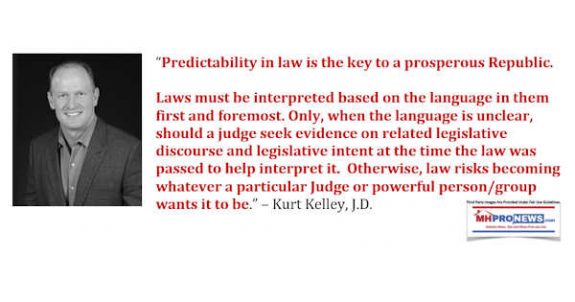

Look again at Tony’s graph, and what happened when things stopped going well for the industry in the early seventies. That’s why there was so much resistance to the HUD standard, and still is. That’s why it has always been hard to get those “big manufacturers” to spend “just a little bit more” on the want-of-the-week. If the competition doesn’t do the same, you’re toast. Real competition is not for the faint of heart, but it works wonders for customers.

Competitive product improvement, step by step. Learning curve. That’s how the MH industry cut the cost of building homes in half. Focused, efficient, production in a housing market where nobody was in charge, regulation was rampant and good times were rolling. Don’t hold your breath waiting for a repeat of that kind of housing opportunity.

My enthusiasm for today’s outlook is based on the fact that the leaders have survived and now have commanding market share, while retaining—improving—their production cost advantage over the stick guys. I don’t know what the Big Three’s margins are, but they’re profitable. We’re in a new and potentially better ball game.

The outlook is marred by the yo yo of housing demand, fluctuating with the whims of the economy and regulators. That’s why, when asked to write a book on the potential of manufactured housing, I said, “You’ve got to be kidding!”

It didn’t take much research to change my mind. The survivors seem to have learned to cope with such market volatility and stifling regulation. The production cost advantage is still increasing and the competition continues to doze. Well managed surviving MH producers remain profitable in a scenario that would have crushed any normal manufacturing industry long ago … but woe to the manufacturer who single-handedly takes on the cost of a major industry image upgrade.

It needs to be done, but has to be a team effort, with participation by most members of the industry at large. And there has to be strong leadership so we all head the same direction.

Given the squabbling we all see and regret, is there any hope?

Of course there is! The MH industry has always been a teamwork affair, where even bitter enemies worked together to keep the system functioning, because we all had a vested interest in keeping this marvelous housing system pumping, cranking out houses and profits. That has not changed.

Sure HUD, Dodd-Frank and their ilk are a royal pain in the butt, but they strangle the other guys, too. Despite best efforts of bureaucrats to rule by regulation, economics will win in the end, and we’ve figured out an inherently better way to build houses.

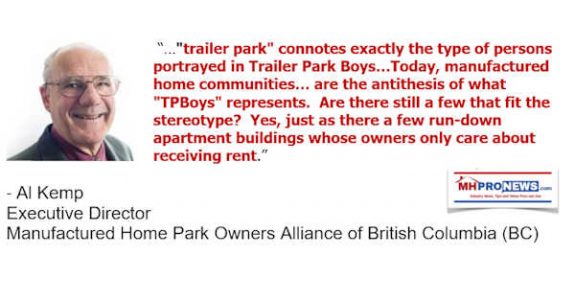

Yes, for a time we fouled our nest. Young industries do that. Yes, the public disdains “trailers.” Tell me what sort of low cost housing they like? Nobody wants low cost housing except those having a nose for value or low income. Those are huge markets that no other product can satisfy that need as well as manufactured housing.

What we lack in image, we more than make up in value.

Let’s build on that. ##

.png) Bob Vasholtz is the author of Dueling Curves. Bob Vahsholtz is the author of DUELING CURVES The Battle for Housing. Bob can be reached at kingmidgetswest@gmail.com. Web: www.kingmidgetswest.com

Bob Vasholtz is the author of Dueling Curves. Bob Vahsholtz is the author of DUELING CURVES The Battle for Housing. Bob can be reached at kingmidgetswest@gmail.com. Web: www.kingmidgetswest.com

A prior guest column from Bob – Who's in Charge Here – is linked.

(Editor's Note: The chart show above is courtesy of CalculatedRisk and was used in the following article, Manufactured Housing's Declaration of Independence. As with all letters to th editor, articles and guest column, the views represented are those of the writer. Other perspectives are welcome, email latonyk@gmail.com with Letters to the Editor or OpEd in the subject line.)

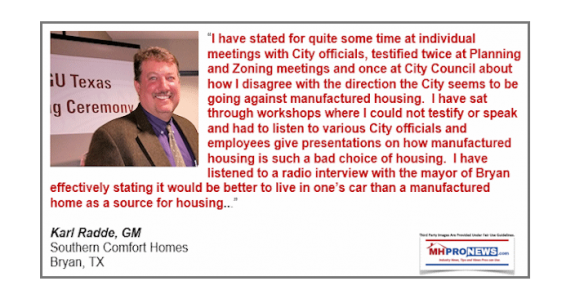

Karl Radde – TMHA, MHI, Southern Comfort Homes – Addressing Bryan City Leaders, Letter on Proposed Manufactured Home Ban

To All Concerned [Bryan City Officials, Others]: As the retail location referenced by Mr. Inderman, I would like to take a moment to address the …